The prototype Consolidated Vultee B-24 Liberator flew on December 29th 1939. It went into production in 1940 for the US, British and French. There were many versions of this successful aeroplane. The main function was as a bomber, but it was also converted to be used as a transporter and for photo reconnaissance. Brief details can be found here. The Liberator was finally withdrawn from production on May 31, 1945 with over 19000 having being built.

The B-24 H 25FO “Hookem Cow”, modelled by John Deacon, was built by the Ford motor company in their factory at Willow Run, Michigan in March 1944. The name “Hookem Cow” came from a popular nightclub in Chicago. It was one of the first produced in a natural metal finish and was built at a time when the Ford company was manufacturing a Liberator every hundred minutes, twenty four hours a day, seven days a week! This Liberator arrived in the UK in August 1944 and was assigned to Captain John. L. Ollom of the 755th bomb squadron. The artwork on the starboard side is a portrait of Captain Ollom’s wife. The aircraft was based at Horsham, St. Faith, Norwich, England and took part in over fifty missions with many bombing operations over Germany. It was destroyed on take off at Horsham on 14th April 1945 where five of the seven crew were killed.

John’s model looks real in flight (Cosford 2001)

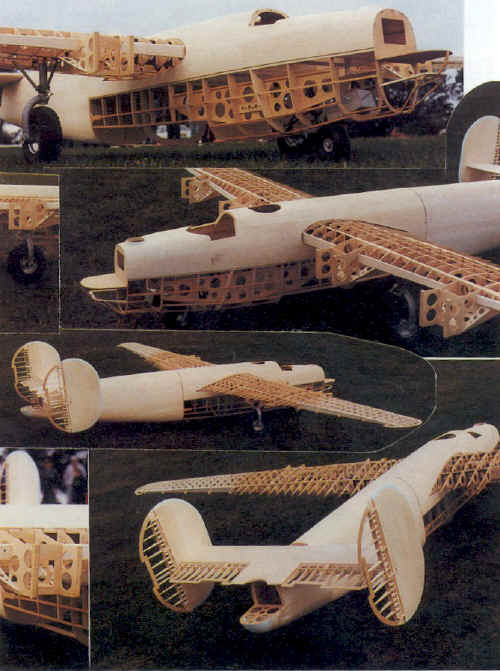

It was in October 1995 as a result of John seeing a friend’s 1/6 scale Flying Fortress under construction that John became interested in the prospect of building a B-24. It was only after deciding to build a model of “Hookem Cow” (simply because a colour picture of the nose art was available) that the research really started. It took approximately 1700 hrs and 3.5 years to complete the project.

John began by produced drawings from a 1/72 three view drawing published many years ago in a magazine – Aviation News. The model was built predominately from balsa wood, liteply, spruce and aircraft grade plywood.

The fuselage is built around a crutch of 1/4″ x 1/2″ balsa with the top half formers of 1/8″ liteply. Spruce stringers of 1/4″ square are topped with 1/8″ balsa sheeting. The nose gear is mounted on a 1/4″ ply former which, via a 1/16″ ply doubler, transfers loads to the 1/4″ ply formers positioned at the front and rear mainspar. The rear fuselage was constructed in a similar fashion, but with liteply formers. To attach the two halves together, the front section has seven stainless steel plates with blind nuts attached around its circumference. The rear has stainless steel tongues for the bolts.

The tailplane and fins are conventionally built with 1/16″ glass epoxy “T” spars fitted between fins and tailplane.

The wings use 1/8″ ply and liteply ribs. Sheeting is 3/32″ balsa.

Storage and transport of the model had to be considered carefully. The model can be split into seven sections: front and rear fuselage; two inner wing sections; two outer wing panels and the tailplane.

The retractable, pnuematic, undercarriage was designed by John around industrial trolley wheels and machined by Geoff Sergent. The main legs use specially made aluminium castings.The system operates around a 3/4″ steel tube mounted between and through the main spars. A commercial 20mm cylinder and pressure of 150 psi allows four to five cycles. The nose wheel is retracted electrically using a Mike Reeves servo.

There is a lot of scale detail on the model as shown in this illustration of the cockpit.

There are functional bomb doors, driven using electric screwdriver motors.

Fowler flaps are also included and can be used in two stages.

The entire model was covered in glass cloth and epoxy resin and then covered in 0.15mm lithoplate (except the flying surfaces). Frequent annealing was required on some of the plates because of the compound curves. Rivets were added on the reverse side of the panels using a dressmakers starwheel. The lithoplate was applied using Evostick contact adhesive.

There is no lead needed to balance the model. The balance point was achieved by careful position of the batteries. It was also helped by the relatively long nose of the aircraft and the nose wheel assembly.

The radio system consists of two JR PCM receivers. The servos are powered by two 6v, 4Ah Nicad batteries and the receivers by two 6v, 900mAh batteries.

The 24 servos used are:

| Function | Servo |

|---|---|

| Throttle (4) | NES 517 |

| Aileron (2) | HS700BB |

| Elevator (2) | HS700BB |

| Rudder (2) | HES605BB |

| Flap (4) | HS700BB |

| Main undercarriage (2) | S148 |

| Stearable nosewheel | HES605BB |

| Retract nosewheel | S148 |

| Nosewheel doors | S148 |

| Bomb doors | S148 |

| Bomb release | S148 |

| Brakes | S148 |

| Tailskid lock | S148 |

| Ball turret | S148 |

John and his model.

As a tribute to the five crew who died in the aircraft, John has a small piece of the full-size “Hookem Cow” in the front turret of his model. This he recovered form the actual crash site.

John says that it is a joy to fly. It certainly looks very real in the sky.

The model being pushed out to fly at Cosford 2001.

For event tickets, merchandise and more visit our online shop.