This page is in response to a post and a number of comments in the Forum, if you have a better way of doing things, let me know and it will go on this page.

For a starter , making and fitting a throttle linkage to a Zenoah 38 or similar engine with a Walbro carburettor.

There, however, is always an alternative way of doing things: –

Instead of making a ply bracket to hold the bellcrank, the hexagonal drain plug that is on the side of the engine can be blind drilled and tapped for a pivot pin to hold the bellcrank.

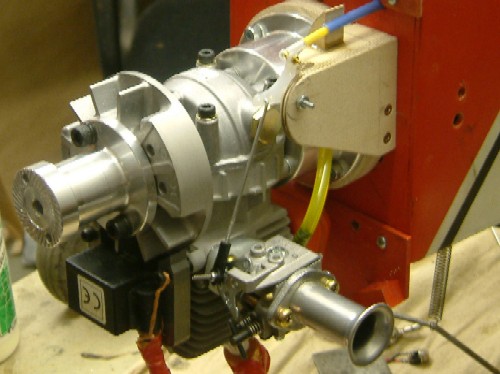

This method uses a servo inside the fuselage. occasionally, I prefer to mount a servo directly over the carburettor with the servo arm aligned with the angle of the carburettor lever. (see picture below)

Either way, the spring on the throttle arm should be moved back one hole so there is less tension when driving the arm. DO NOT remove the spring, it’s there to stop the butterfly spindle chattering and wearing the body of the carburettor.

Here is a shot of No.2 Caribou throttle servo in it’s ply mounting, prior to fitting the Z26 engine. This illustrates the alternative method I prefer.

Do not make the mounting too flimsy, as this may allow the servo to move in flight and then you will get a poor response with the throttle.

For a number of years, many LMA members have been using this wood instead of the traditional spruce for longerons and spars, it enjoys superior mechanical properties that make it a better choice.

For the benefit of all modellers shown below is a table of the mechanical properties to aid your design efforts or just to provide further information.

Click here for a word copy of the Technical Data.

If you want other tip and tricks here, let me know by e-mail.

For event tickets, merchandise and more visit our online shop.